Adhesive Peel Tester manufacturing|peel testing equipment : distribution An investment in a Peel Strength Tester acts to solve the critical needs of adhesive testing of a manufacturer and gives him the freedom to optimize his operations, reduce costs, and improve . A university which continues to innovate and lead in the ever-competitive global higher education sector. One which thinks and acts both locally and across borders and cultures to promote the development of a global mindset as an integral part of the Nottingham student and staff experience.

{plog:ftitle_list}

30 de ago. de 2023 · The list of Omniheroes Dawnbringers Synergymates according to their rarity are listed below: Legendary: Themis, Atropos, Albert, Salleine, Marlena, .

An investment in a Peel Strength Tester acts to solve the critical needs of adhesive testing of a manufacturer and gives him the freedom to optimize his operations, reduce costs, and improve .Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive .

The phase angles must be known in order to assess and perform a peel test, and the adhesive strength varies with peeling angle. Methods of testing range from the following. Single-coated, peel at a 180-degree angle. . Experience in hardware design, cost optimization, and high-volume manufacturing operations. Ph.D. in Electrical and Computer .Cut and peel testing. Cataplasma testing – This is similar to the ‘cut and peel’ test process, but still not exactly the same. This test will put the adhesive through a similar climate in which the end-product will likely be exposed. So, . To ensure quality, manufacturers of products like tape, labels, and wallpaper rely on adhesion testing. Without proper bonding between materials, it is possible for products to peel away or fail prematurely, which could . ISO 11343 is a standardized Wedge Peel Impact test method used to measure the resistance of high-strength structural adhesives to cleavage fracture at various speeds and user-defined temperatures. The impact test consists of a wedge with a defined shape and mass, being driven at a defined velocity into the adhesive bond securing two metallic .

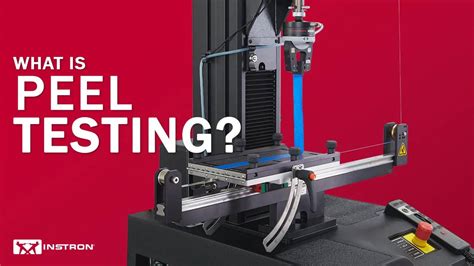

what is peel testing

Testronix Peel Strength Tester provides exceptional performance, user-friendly interface, and versatility in testing results for ensuring the quality and durability of adhesive bonds in paper & packaging instruments. Mr. Faizal Khan . Unlock the Power of 3 Exceptional MachinesAdhesive testing . Our expert adhesive consultants can test tapes , test labels , and other adhesive coated products. PSTC, ASTM, FINAT, AFERA, SAFT testing . 180 degree peel. ISO 11339:2010 Adhesives -- T-peel test for flexible-to-flexible bonded assemblies. ISO 29862:2018 Self-adhesive tapes -- Determination of peel adhesion properties. ISO . The Peel strength tester can accurately point out the shortcomings in a product by precisely calculating the force to separate two parts joined by an adhesive. By analyzing both the adhesive strength and bond quality- manufacturers can make informed decisions on the type of materials to use for their products to enhance their quality and have .

Digital Plastic and Rubber Thickness Meter store

Our materials scientists conduct peel testing along with a suite of physical and mechanical testing to generate accurate data that delivers the insight you need to develop and test new adhesives, coatings and polymer laminates for wide range of applications such as labels, packaging, automotive, medical devices and construction.The Peel Adhesion Tester - UniTest is highly configurable testing equipment. The tester can conduct 90 degree, 180 degree and loop tack peel adhesion tests. . tags: adhesive test, adhesive test equipment, adhesive test machines, adhesive tester, adhesive testing, positest pull-off adhesion tester, coating adhesion tester, portable pull-off .Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330Label Testing Equipment. When manufacturing qualified labels, manufactures should have several considerations in designing and processing: . C620H Friction / Peel Tester is used for testing the coefficient of friction and peel strength of plastic film, paper, packaging materials and more. . CZY-8SA Lasting Adhesive Tester can be used to .

peel testing system

The Peel Strength Tester is one of the most popular testing instruments that is used in the packaging and adhesive industries to test the strength of the adhesives. The following tests can be conducted on one single instrument: 1. Adhesive strength test 2. Peel strength tester 3. Seal strength test 4. Bond strength testThe bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.A peel tester, which is also called an adhesive tester or an adhesion tester, is an instrument especially used to assess the peel strength/adhesive strength of an adhesive substance (bonded together). . In the manufacturing world, ensuring the reliability and excellence of adhesive bonds is important throughout numerous industries, including .

The peel test is used to determine the force required to remove the bandage from the skin, tissue or other adhesive tape. The aim of research is to study the factors that affect the performance of adhesive bandage—starting . Adhesive bandage manufacturing, peel test, adhesive tape machine settings, storage of adhesive tape. Date received: 26 May 2018; accepted: 22 March 2019.

The 180° peel adhesion test is a vital component of quality assurance in adhesive manufacturing. By following ASTM D3330 guidelines and utilizing advanced testing equipment like the Cell Instruments 180° peel adhesion tester, companies can ensure that their products meet rigorous industry standards. A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .

Each of these adhesives or tapes will have been tested in both the development stage and as part of the manufacturing process to ensure consistent quality. . Peeling test metal-honeycomb core BS EN-28510-1 – Adhesives. Peel test for a flexible-bonded-to-rigid test specimen assembly. 90° peel ISO 90 Degree Peel Tests ISO-8510-1 .

ISO-8510-1 – adhesives – peel test for a flexible-bonded-to-rigid test specimen assembly – part 1: 90° peel ISO-8510-2 – adhesives – peel test for a flexible-bonded-to-rigid test specimen assembly – part 2: 180 ° peel SAE-J 1553 – cross peel test for automotive-type adhesives for fiber reinforced plastic (FRP) bonding

ASTM D1876 | Adhesives | Peel Testing. ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded in the machine before the test. Other common peel tests are the .

The instrument is called a Peel Strength Tester or a Peel Tester machine, advanced in design and made only for testing adhesive peel strength on various material combinations. . The use of adhesives in modern manufacturing these days has become part of the mainstream. From packaging to automotive assembly, it's used practically everywhere. .A peel test is a basic form of mechanical testing that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).ASTM D3167 is a standard test procedure used to measure the average peel strength or force of an adhesive and bonding agent by using a floating roller peel fixture. This test can be used to compare adhesives or to compare adhesive surface preparation procedures. ASTM D3167 is therefore often used in product development and manufacturing procedures. The Electronic Peel Tester is a specialized device used to assess the adhesive strength of materials, particularly in packaging, textiles, and manufacturing industries.

Pipe wall Thickness Meter store

One of the best testing machines is the peel strength tester. . Peel Tester-Easy Tool to Measure the Adhesive Performance Of Tapes. If you work in the manufacturing industry, then you must have an idea about the adhesive performance of tapes. These tapes will play a major role in determining the holding capacity of the package. Here, tape may be peeled at a consistent 90° or other angle via specialized fixtures. Tape is applied to the surface of the fixture, and the loose end is then secured by a grip. As the grip pulls upward, the fixture moves horizontally, maintaining the desired angle for the duration of the test. Another type of peel testing is the loop tack test.

peel testing software

Dumbbell Sample Cutter store

LCD Melt Flow Indexer store

The latest tweets from @AnaSchultz__

Adhesive Peel Tester manufacturing|peel testing equipment